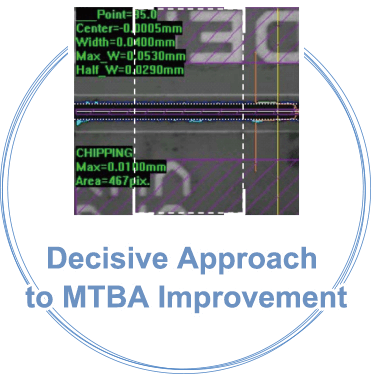

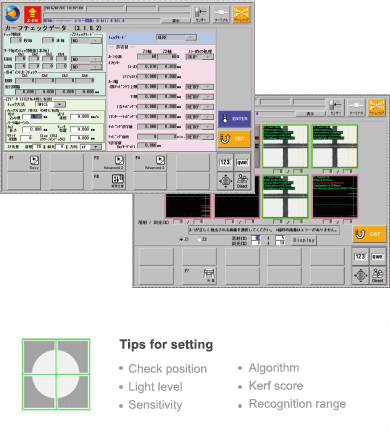

Kerf check errors can be significantly reduced by making appropriate settings

for your device and the blades you are using.

for your device and the blades you are using.

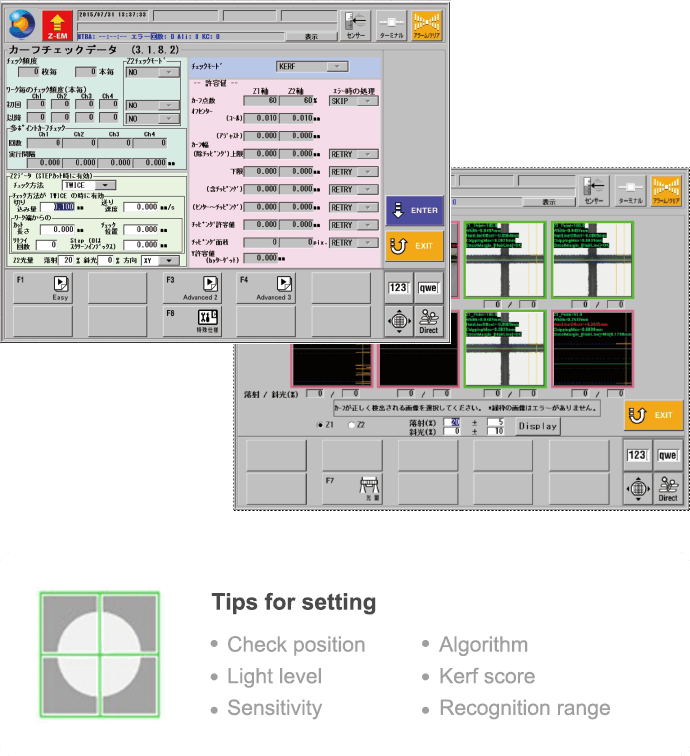

Kerf check errors can be significantly reduced by making appropriate settings

for your device and the blades you are using.

for your device and the blades you are using.