Newly Developed Die Separator for Hard Materials Such as SiC

DISCO Corporation, a semiconductor manufacturing equipment manufacturer (Head Office: Ota-ku, Tokyo; President: Kazuma Sekiya), has developed DDS2020, a fully automatic die separator that supports Φ200 mm tape frames and achieves separation of hard materials including SiC and sapphire.

This equipment will be exhibited at SEMICON Japan 2023 (December 13-15, Tokyo Big Site).

Developmental Background

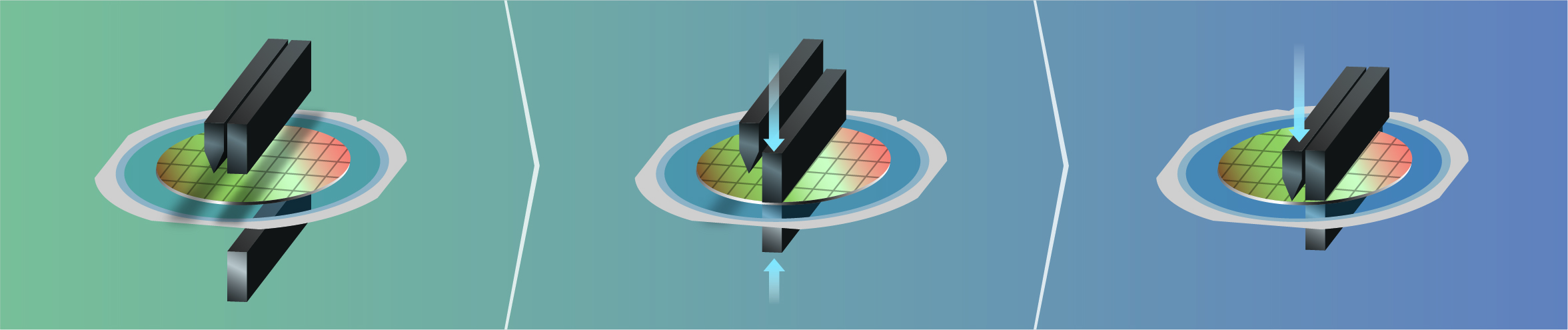

Stealth dicingTM is a dicing process where a modified layer is formed by focusing a laser beam inside the workpiece, following which stress is applied externally to separate it into die. As silicon wafers can be separated with a relatively small amount of stress, the die can be separated by simply expanding the dicing tape. On the other hand, materials that have high mechanical strength like SiC wafers that are widely used for power devices and sapphire wafers used for LED cannot be separated just by expansion. Thus, a breaking mechanism was necessary.

DDS2020 is a die separator that achieves separation of hard materials such as SiC and sapphire with a low load using a new breaking mechanism.

Features

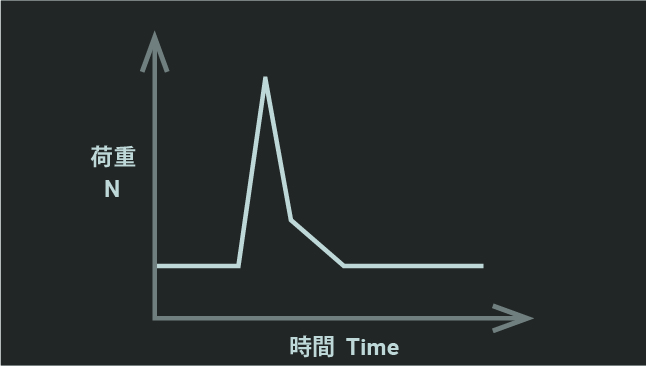

- New breaking mechanism that achieves low load separation

- Load decreased by 40% compared to the conventional breaking mechanism

- Breaking load measurement and graph display

- Detects unseparated die and improves the yield

- Automatic retry setting when unseparated die are detected is also available

- Tape frame remounting*1 for breaking is no longer necessary

- Eliminates remounting work and reduces tape costs

*1: Conventionally, Φ200 mm wafers needed to be remounted on a Φ300 mm tape frame when performing breaking. This is no longer necessary.

Future Schedule

| To be exhibited at SEMICON Japan 2023 | December 13 to 15, 2023 at Tokyo Big Site |

|---|---|

| Test cuts | Accepting requests |

| Sales release | Accepting orders |

About DISCO Corporation

DISCO is a semiconductor equipment manufacturer that provides precision processing equipment, including dicing saws and grinders, and precision processing tools (blades and wheels) used for manufacturing semiconductors and electrical components. In addition to these products, as a result of pursuing optimal processing results for customers through the provision of the technology used in the equipment and tools, DISCO products and processing technologies have been widely adopted by device manufacturers and semiconductor subcontractors domestically and internationally. For details, please view the DISCO website www.disco.co.jp.

Contact

Please feel free to contact us with any questions or inquiries.