Development of DFG8020 and DFG8030

to support diversified package grinding needs

Introducing two models to the market simultaneously

DISCO CORPORATION (Head Office: Ota-ku in Tokyo; President: Kazuma Sekiya), a semiconductor manufacturing equipment manufacturer, has developed two types of fully automatic grinders that support diversified package grinding needs. DFG8020, compatible with the maximum 390 x 390 mm sized panel-level packages, and DFG8030, which processes strips (elongated substrate), will be introduced to the market at the same time. Both models will be exhibited at SEMICON Japan Virtual, which will be held December 14–17, 2020.

R&D Background

The number of parts used for high-end mobile devices, including smartphones, is increasing with the start of 5G service. Adoption of high-density packaging, including FOWLP* and PLP**, in RF (radio-frequency) modules and power management modules has accelerated, and grinding needs related to lower profile packaging and wiring layer formation are growing.

In addition, resin package configuration has become diversified, with shapes such as round and square, accompanying manufacturing processes such as WLP*** and PLP. Thus, it is necessary for grinders to accept these various types of package configurations, including existing strip substrates (elongated workpieces).

In order to support these needs, DFG8020, which achieves maximum 390 x 390 mm sized package grinding, and DFG8030, which achieves high-throughput processing of strips, have been developed.

* Fan Out Wafer Level Package : packaging method that realizes an increase in the number of pins by arranging singulated die on a wafer and forming a re-wiring layer to pull the wiring out of the die terminal on the outside of the die

** Panel Level Package : method for packaging multiple semiconductor die lined up on a square panel

*** Wafer Level Package : wafer condition before singulation or method for all-at-once packaging of singulated die arranged on a wafer

Product Features

Common Features of DFG8020 and DFG8030

- Fully automatic operation: workpiece loading, processing, cleaning, and workpiece loading to cassette

-

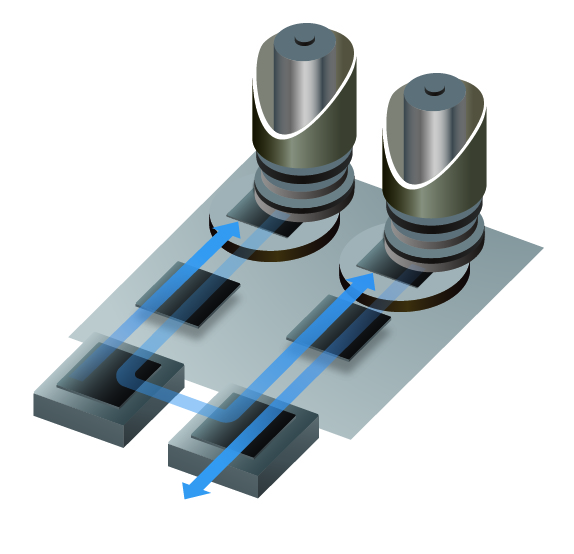

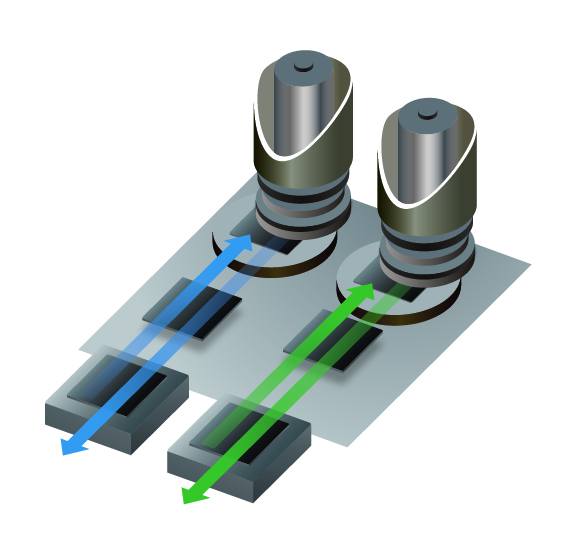

Two spindles, two chuck tables

Workflow Example

Dual axes (from rough grind up to fine grind)

Single axis, parallel processing -

High planarization grinding by optimizing processing points

- Ensures rigidity and stability of the processing axis through design on the assumption of usage of a large diameter grinding wheel (Φ500 mm)

- Prevents flatness irregularities from occurring in the workpiece

-

Switchable grinding method

- In-feed grinding performed through rotation of both chuck table and grinding wheel

- Creep-feed grinding performed by feeding the workpiece to the rotating grinding wheel

DFG8020

Fully automatic grinder supporting panel-sized workpieces

- Compatible with maximum 390 x 390 mm workpieces and tape frame**** for Φ300 mm

-

Size and weight

(W) 1,660 × (D) 4,400 × (H) 1,800 mm, approx. 5,700 kg

DFG8030

Fully automatic grinder with a transfer mechanism for strips

- Compatible with strips (45–100 mm x 150–300 mm) and small diameter wafers*****

-

Achieves simultaneous grinding of multiple workpieces with high-throughput

Workpieces placed on the processing table - Controls removal amount by measuring workpiece thickness through non-contact measurement***** during processing

-

Size and weight

Processing section: (W) 1,660 × (D) 2,300 × (H) 1,800 mm

Transferring section: (W) 2,500 × (D) 1,500 × (H) 1,800 mm

Weight: approx. 5,950 kg (total of processing and transferring sections)

**** User-specified

***** Optional

Schedule

| SEMICON Japan 2020 Virtual | December 14–17(exhibition contents available until January 15, 2021) |

|---|---|

| Test cut | Now accepting requests |

| Sales release | September 2021 |

About DISCO

DISCO is a semiconductor equipment manufacturer that provides precision processing equipment, including dicing saws and grinders, and precision processing tools (blades and wheels) used for manufacturing semiconductors and electronic components. In addition to these products, as a result of pursuing optimal processing results for customers through the provision of the technology used with the equipment and tools, DISCO products and processing technologies have been widely adopted by device manufacturers and semiconductor subcontractors both domestically and internationally. For details, please visit the DISCO website at www.disco.co.jp.

Contact

Please feel free to contact us with any questions or inquiries.