Observation and Measurement of the Processed Shape After Dicing

Dicing Saws Equipped with a “3D Profiler” to be Shipped from May

DISCO CORPORATION, a semiconductor manufacturing equipment manufacturer (Head Office: Ota-ku, Tokyo; President: Kazuma Sekiya), has released an optional function, the “3D Profiler” that enables observation, measurement, and recording of the processed shape after dicing. DFD6363, a fully automatic dicing saw that supports ø300 mm wafers, will additionally be equipped with this function starting with shipments from May 2023.

Release Background

In line with the advancement of technologies such as electrification and driving assistance systems for passenger vehicles, the presence of automotive semiconductors that require high quality has increased. Under these circumstances, DISCO users have also started to require stricter processing quality management. DISCO has accumulated expertise in optics-related technologies since the first launch of laser saws in 2002, and in 2016, a “Minimal 3D microscope” to observe and measure the various shapes of minimal wafers after processing was released. This measurement system was miniaturized, incorporated into laser saws to measure the kerf, and sold in 2018. This time, the system has been optimized for and incorporated into dicing saws as well.

With regard to the processed shape for dicing saws, observation and measurement functions using two-dimensional images have been incorporated into the equipment since the late 1970s. However, this function will be one of the biggest evolutions in half a century since it makes three-dimensional kerf shape management possible.

Features of the “3D Profiler”

This is an optical interferometric microscope used for non-contact observation and measurement of the processed shape after dicing.

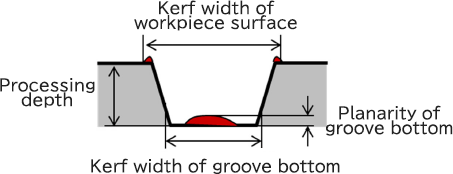

It is possible to three-dimensionally observe, measure, and display the following items: the cut width (kerf width) and edge surface shape of singulated die after full-cut dicing, and the groove depth and groove bottom planarity during half-cut dicing (grooving).

In addition, traceability can be improved by saving this data to the equipment as quality records.

Major items that can be measured using the “3D Profiler”:

Example of observation and measurement images:

Future Schedule

This function can be installed on DFD6363.

Please contact a DISCO sales representative regarding other applicable models and retrofitting.

About DISCO

DISCO is a semiconductor equipment manufacturer that provides precision processing equipment, including dicing saws and grinders, and precision processing tools (blades and wheels) used for manufacturing semiconductors and electronic components. In addition to these products, as a result of pursuing optimal processing results for customers through the provision of the technology used with the equipment and tools, DISCO products and processing technologies have been widely adopted by device manufacturers and semiconductor subcontractors both domestically and internationally. For details, please visit the DISCO website at www.disco.co.jp.

Contact

Please feel free to contact us with any questions or inquiries.