DISCO Develops Hub Blades with High Quality-Standards: Sales of “ZH05 Prime Grade” to Be Officially Expanded

DISCO CORPORATION will officially expand the sales of the ZH05 prime grade, which has higher product quality standards than the mainstream “ZH05 series” of precision processing hub blades.

Background and Purpose

In recent years, the demand in semiconductor devices for automotive applications and medical equipment has been growing considerably. Because an unexpected failure may cause a serious incident, such devices require high product-reliability. Thus, variation in processing quality in each manufacturing process needs to be minimized.

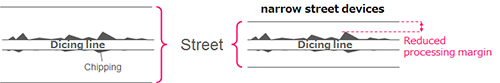

In addition, the street (dicing line) is becoming narrower for small-chip devices (e.g. discrete devices) to increase the number of chips produced from one wafer. When the street becomes narrow, the processing margin is also reduced*1. For this reason, the processing quality variation needs to be minimized.

With this in mind, prime grade products which have higher specifications in kerf width, blade exposure accuracy, and concentration were added to the ZH05 series (the mainstream hub blade) to further minimize quality variation in the processing tool, which can cause variation in processing quality. By 2020, 60 to 70% of the blades in the target markets are expected to be replaced. We will increase our supply of products according to the market size.

Features of the Product

Sets the three most important specifications with half the variation range of standard products

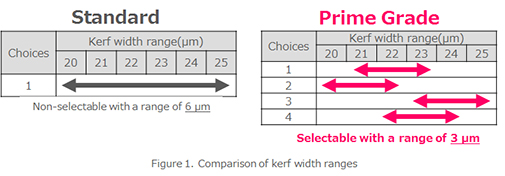

Kerf Width

- Standard: Non-selectable with a range of 6 µm

- Prime grade: Selectable with a range of 3 µm

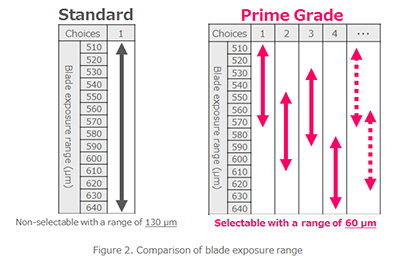

Blade exposure accuracy

- Standard: Not selectable with a range of 130 µm

- Prime grade: Selectable with a range of 60 µm

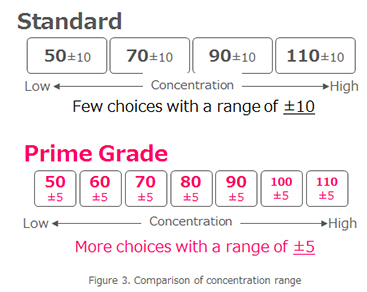

Concentration

- Standard: Few choices with a range of ±10

- Prime grade: More choices with a range of ±5

Measured to further improve quality

Chipping Inspection for All Blades

- Before shipment, silicon die are processed and the front side chipping is automatically measured using image processing. Only products that have passed the highest of inspection processes are shipped.

Contact

Please feel free to contact us with any questions or inquiries.