Development of a System for Monitoring and Control of Precision Processing Equipment using a Smartphone or Other Device

DISCO CORPORATION, a semiconductor manufacturing equipment manufacturer (Headquarters: Ota-ku, Tokyo; President: Kazuma Sekiya), has developed a system for monitoring and controlling multiple units using a smartphone, PC, other device. This system will be exhibited as a concept model at SEMICON Japan 2018 (December 12 to 14 at Tokyo Big Sight).

Overview of Equipment Monitoring and Control System

This system monitors and controls multiple precision processing units interactively using devices such as a smartphones or PCs.

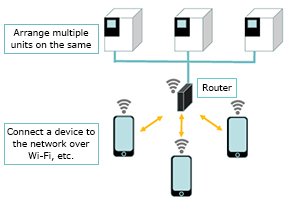

- Monitoring and controlling by arranging multiple units on the same network

The conventional monitoring and control system required equipment to be monitored individually. By arranging multiple units on the same network and connecting a device to the network through Wi-Fi, multiple units can be monitored and controlled centrally by an operator in a remote location.

- Timeline and chat format

When you send a message to multiple units using a device, you will receive responses from each unit. Moreover, you can receive messages from the equipment when operation starts/ends and when an error occurs. The "operation status," "blade type and wear amount," "error occurrence," and other operations, which were originally monitored and controlled on each unit’s monitor, can be handled* in a remote location. The chat history will be displayed in timeline.

*Some operations have been intentionally removed from the settings for safety reasons.

Advantages

Centralized operation in a remote location

- Equipment downtime reduction

The monitoring and control operations, which were originally performed by operators using the equipment monitor, can be performed centrally in a remote location, contributing to equipment downtime reduction. For instance, equipment downtime can be reduced by bringing replacement cassettes and blades to the equipment site when notifications for wafer cassette replacement for one unit and blade replacement for another unit are received. - Operator cost reduction

Semiconductor manufacturing equipment installed in a clean room can be monitored and controlled outside the clean room. Thus, the time required for operators to enter/exit the clean room (e.g., changing into lint-free clothes and passing through an air shower) can be reduced.

Use of web browser

- No dedicated device requirements

Using a web browser, the existing internet environment can be utilized, making installation of a dedicated application or software unnecessary. This allows operators to use PCs, tablet devices, or smartphones that are normally used for other purposes. In addition, operators do not need to share a device because the same equipment group can be monitored and controlled using multiple devices.

Schedule

| December 2018 | Exhibition at SEMICON Japan 2018 |

|---|

Contact

Please feel free to contact us with any questions or inquiries.