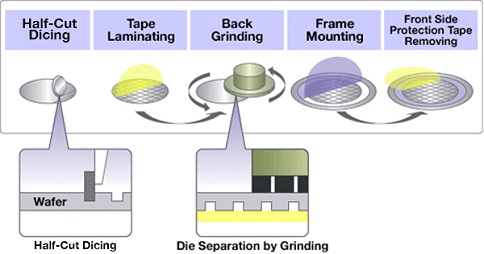

DBG (Dicing Before Grinding) Process

Solutions

Outline of DBG Process

DBG reverses the usual process of fully dicing the wafer after grinding. In DBG, first the wafer is half-cut with a special dicing saw. Then, die singulation occurs when the wafer is thinned below the level of this cut. The wafer then goes to the in-line DBG Mounter, which gently peels off the protective grinding tape, completing the process.

Because in DBG thinned wafers are never transported, wafer-level breakage is greatly reduced; and because die separation occurs during the grinding process, the backside chipping associated with thin-wafer dicing is kept to a minimum. DBG also offers exceptionally high die strength. For these reasons, DBG is an excellent process for processing 300 mm wafers into high-quality, ultra-thin die.

Related Information

Products for DBG process

https://www.disco.co.jp/eg/products/index.html?id=dbg

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details