Introduction of the Gettering DP wheel

Application processing examples

When the silicon wafer is polished, there has been a problem to date where the gettering

effect*1 is lost while die strength rose.

This introduces the Gettering DP wheel that enables polishing that combines high die strength and the

gettering effect.

*1 The gettering effect is a mechanism that forms crystal defects or distortions (=

gettering sites) inside the silicon wafer (bulk or backside) and then captures impurities in these

gettering sites.

Gettering DP wheel introduced this time forms the gettering site due minute scars on the wafer

backside, capturing the heavy-metal impurities.

Conventionally: approach from grinding

The DISCO lineup includes UltraPoligrind (UPG), which achieves high die strength while maintaining a gettering effect. UPG achieves die strength greater than or equal to that with Gettering DP, but the DGP series Z3-axis must be retrofitted with the grinding specification.

Gettering DP: approach from polishing

Gettering DP is a DP wheel that can achieve a gettering effect while maintaining die strength (minimum value) equal to that with UPG and can be installed as is with the Z3-axis DP specification standard on the DGP series.

Gettering DP processing results

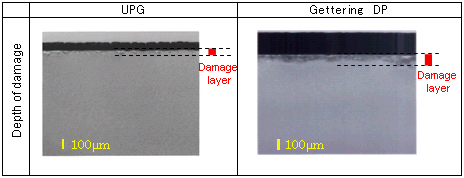

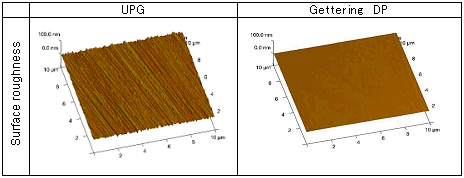

The depth of damage with Gettering DP is about 50nm same as UPG. Moreover, the UPG surface is rough due to grinding with abrasive grains as opposed to the Gettering DP mirror surface from the polishing process.

In die strength (ball-bending), Minimum value almost equal to the stress relief by UPG is achieved. (Figure.1)

For detailed process methods, please contact the head office Applications R&D Department.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details