Uniformed Surface Roughness Variation in PZT Grinding

Application processing examples

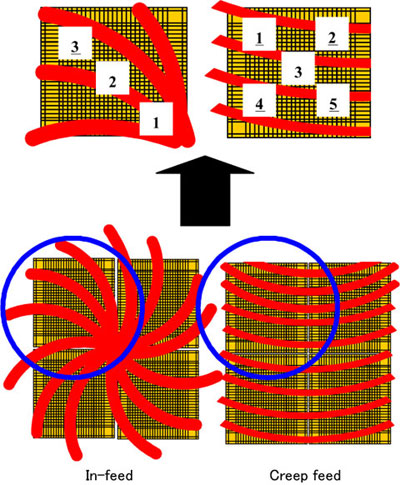

When grinding PZT (piezoelectric zirconate titanate), which is commonly used as piezoelectric material, surface roughness varies among die on the surface. This variation can be reduced by applying “In-feed and Creep feed Grinding”.

Reducing the surface roughness variation in PZT grinding leads to the stability in the following features.

- Converting pressure to electricity

- Converting electricity to vibration and displacement

- Converting electricity to vibration and then reconverting to electricity

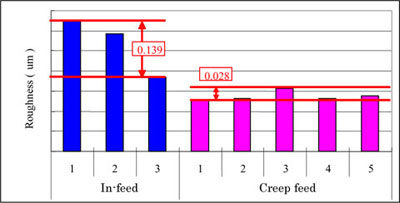

Compared with in-feed grinding, creep-feed grinding is more effective as a measure to prevent surface

roughness variation.

It is possible to reduce the surface roughness to about one fifth.

For details, refer to the below drawing.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details