Process using the 3-point edge alignment

Application processing examples

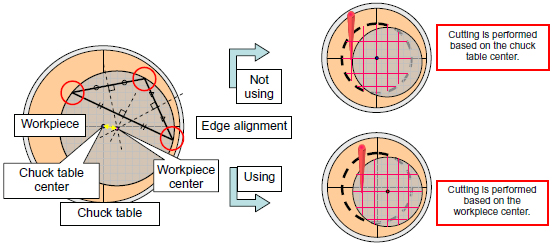

Edge alignment is the process where the workpiece edge is detected and the cutting points are calculated based on that edge.

3-point edge alignment process details

Workpiece position deviation from the chuck table center is detected by calculating the center position and the diameter of 3 edge points of the round workpiece. That information is reflected to the X and Y axes cut limits.

Example of the process using the 3-point edge alignment

-

Countermeasure for flying triangular die (cut completion point correction software)

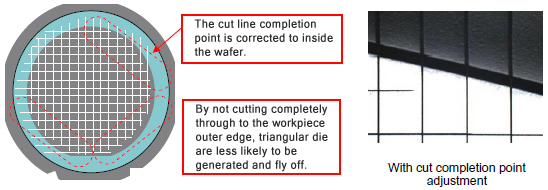

This process stops cutting short of the wafer outer edge to suppress the generation of the triangular die (edge material).

It becomes possible to set the cut completion position at a precise point by recognizing the exact placement position and diameter of the wafer.

- Countermeasure for tape damage during laser processing

When the tape area outside the workpiece is irradiated during laser processing, holes are opened in the tape from which the vacuum leaks. By using edge alignment that recognizes the workpiece diameter and placement on the chuck table, it is possible to avoid the laser irradiation of the tape.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details